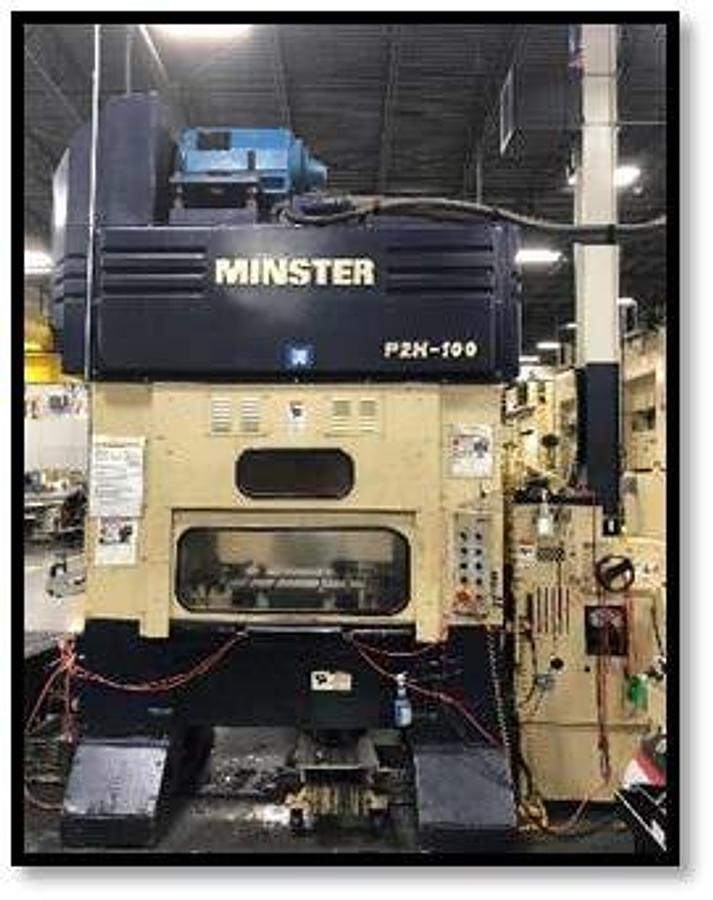

MINSTER MODEL P2H-100 STRAIGHT SIDE PRESS

MINSTER MODEL P2H-100 STRAIGHT SIDE PRESS

Contact us for price

Description

P2H-100-48X32-F-029990

Specifications (U.S.)

Press Specifications

Shutheight Indicator Readout ...................................................... Inches

Capacity off Bottom. .................................................................... 112 Tons at 0.063 in

Crankshaft Extension Length ....................................................... 3.40 in

Crankshaft Extension Diameter ................................................... 2.50 in

Crankshaft Extension Location .................................................... Opposite Drive Side

Drive Arrangement ...................................................................... Flywheel

Drive Location ............................................................................. Left Hand Side

Lube Unit Location ...................................................................... Drive Side

Approximate Press Weight .......................................................... 41,000 Lbs.

Press Slide Specifications

Stroke, Speed ............................................................................... 2.95 in, 300 SPM

Adjustment of Shutheight ............................................................ 3.94 in

Length of Quick Lift .................................................................... 0.50 - 4.50 in

Area of Slide, R-L x F-B.............................................................. 48.0 x 26.0 in

Press Bolster Specifications

Bolster Plate Material .................................................................. Cast Iron

Bolster Plate Thickness ................................................................ 5.94 in

Area of Bolster, R-L x F-B .......................................................... 48.0 x 31.5 in

Opening in Bolster, R-L x F-B .................................................... 39.4 x 7.5 in

Press Frame Specifications

Upright Passline Opening, F-B .................................................... 22.0 in

Area of Bed, R-L x F-B ............................................................... 48.0 x 31.5 in

Opening in Bed, R-L x F-B.......................................................... 40.0 x 14.2 in

Bed Deflection ............................................................................. 0.0013 in/ft

Shutheight, SDAU ....................................................................... 12.96 in, on Bolster

Approx. Clearance, Mount to Bottom of Bed .............................. 17.0 in

Approx. Distance Mount to Top of Bolster ................................. 46.7 in.

Approx. Distance Mount to Top of Bed ...................................... 40.7 in

Approx. Floor Space, R-L x F-B ................................................. 104 x 70.0 in

Approx. Overall Area, R-L x F-B ................................................ 104 x 70.0 in

Approx. Overall Height, from Mount .......................................... 155 in

Press Control Specifications

Drive Motor Power, Speed .......................................................... 25 HP, 1500 - 1800 RPM

Drive Motor Starter ...................................................................... Full Voltage Non-Reversing

Incoming Power Drop .................................................................. Control Pedestal

Control Pedestal Location ............................................................ Right Hand Side

Control Station Location .............................................................. Pedestal Mounted

Run Station Location ................................................................... Pedestal Mounted

Setup Station Location ................................................................. Right Hand Side

Limit Switch Type ....................................................................... 16-Pole Programmable

Control Operation Mode .............................................................. Inch-Setup-Continuous

Press Mounted Stop Control PB .................................................. (1) Front and (1) Rear

One Piece High Tensile Cast Iron Frame reduces overall press vibration level. The open top of the frame provides easy access for routine maintenance. Compact Footprint minimizes required floor space.

Bed Deflection designed for specified deflection between tie rod centers with maximum press tonnage distributed over the center two-thirds of the R-L bed area.

Die Lubricant Troughs cast integral with bed

Feed Pads on right and left side of bed for convenience when cabinet style feeding equipment is furnished.

Counterweights on Crankshaft for added stability at higher operating speeds.

Combination Hydraulic Flex Disc Clutch and Brake includes dual clutch valves and provides quick starts and faster stopping times for higher production speeds.

Air Operated Flywheel Brake interlocked with stop circuit eliminates coasting resulting in quicker access to die area.

Pressurized Monitored Lubrication of all main and connection bearings have full film lubrication with pressurized oil supplied to each bearing within the crankshaft. The system is designed to stop the press in the event of reduced oil pressure. The consistent oil film gives the ultimate dynamic bearing stiffness and longevity resulting in better bottom-dead-center repeatability and die life. Includes vacuum switch to monitor condition of filter.

Pass Line Level Slide Guiding System with four (4) hydrodynamic guide posts assures positive centering and resists off-center loads for increased die life.

Wrist Pins designed for 50% of press tonnage snap through.

Hydraulic Motorized Shutheight Adjustment with Digital Readout

Hydraulic Slide Lockup eliminates clearances in slide adjustment parts to reduce the effects of snap-through forces and punch penetration, thus reducing vibration.

Large Hydrostatic Piston Drive for increased tensile stiffness and bottom-dead-center repeatability. Piston drive bearing design promotes prolonged machine accuracy and die life.

Quick Lift Slide for quick die access. Facilitates die inspection and material threading. Ideal when shorter stroke applications are required.

Integral Press Shock Mounts for vibration dampening and bed leveling.

Die Space Guard A-4

An interlocked, point of operation guard for both front and rear of press. Enclosure is designed for applications in which all part and scrap removal is to be done through the bed opening.

FEATURES:

• Pneumatic powered assist for lifting and lowering the doors within two vertical guides.

• Single paned, mar resistant, polycarbonate windows for press operation viewing.

Minster Production Management Press Control includes the following features:

• Color Touch Screen

• Allen Bradley SLC 5/04 PLC

• 16-Pole Programmable Limit Switch

• Brake Monitor / Press Stopping Time Readout

• 75 Tool Storage Capacity with 7-Digit Numeric I.D. Codes

• System Prompts and Diagnostic Messages

• Lube Pump On/Off Indicator

• Motor Start/Stop Control

• Motor Speed Control

• Motor Speed and Load Display

• Slide Adjust Function Indicators

• Dual Clutch Valve Monitor

• Stock Lubricator Interface Output

• Auxiliary output interface for secondary control elements (2nd blowoff, lubricator, divertor tables, etc.)

• Blowoff Valve Interface Output

• Production Counters - Totalizers/Preset/Batch

• Maintenance Reminders - Activated by Predetermined Hours or Clutch Engagements, or Number of Parts Made.

• Press Lifetime Production Record - Hours/Cycles/Clutch Engagements

• Relay Based Primary Machine Control

Pedestal Control Enclosure is ergonomically designed and includes illuminated indicators and operator/set-up buttons and uses minimal floor space. Includes press motor and clutch control circuit with a disconnect switch. Pedestal has standpipe and flexible overhead conduit to swivel box on front of crown.

Control Station Includes:

• Clutch Selector Switch to select Control Operator Mode

• Power Off-On Locking Selector Switch

• Supervisory Control Lock Selector Switch (PMC only)

• Function Enable Illuminated Pushbutton (PMC only)

Set-Up Station facilitates material threading and die set-up and includes:

• Slide Adjustment Control Buttons

• Two-Hand Inching Arrangement

• Stop Button

• Quick Lift Selector Switch

Run Station Includes:

• Two Guarded buttons to operate press

• “Arm” Push-button(s)

• Top Stop Button

• Stop Button

Two (2) Die Safety Block Receptacles (less blocks) located on side of control pedestal.

Clutch and Motor Control Circuits including push-buttons, operate on 110 VAC from control transformer.

Eddy Current Main Drive Motor Without Brake is totally enclosed, fan cooled, variable speed, and provides proven durability and increased torque response.

Minster Production Management (4) Channel Load Monitor

Minster Production Management (16) Point Die Protection

Minster Production Management Automatic Shutheight Adjustment

Minster Production Management Servo Feed Interface

For Minster electric feeds only.

Coil Line Interconnects

Coil Line Interconnects reduce equipment installation and startup time. Electrical interconnects are run in flexible conduit with quick disconnect plugs. All coil line interconnects terminate at a press mounted junction box, located on the press base. Interconnects only apply to Minster manufactured products.

Air Blowoff

Controlled by rotary limit switch and selector switch in control station.

120 VAC Receptacle

Mounted on control pedestal, three (3) amps maximum capacity

Machine Finish

• Crown painted Pulsar Blue: F63-MHS-4389-545.

• Uprights, Slide and Control Pedestal painted Birch White: F63-MHS-4389-294.

• Bed painted Static Black: F63-MHS-4389-313.

Machine finish consists of quality Poulane Paints for chemical resistance, long life, and highest quality appearance. All parts are primer under coated and castings are pre-coated with a smoothing agent providing the best possible paint adhering surface.

Specifications

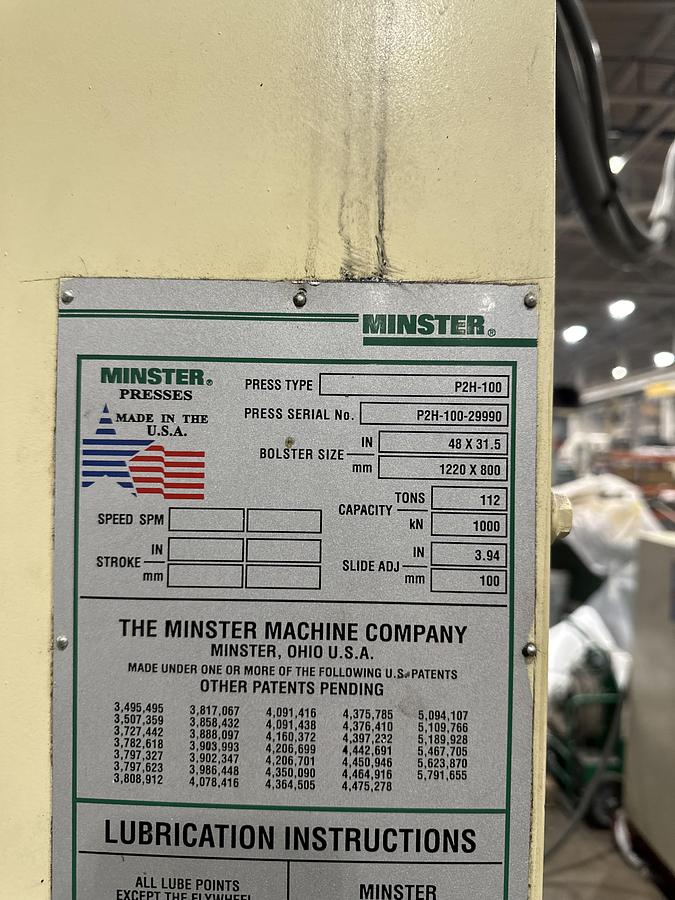

| Manufacturer | MINSTER |

| Model | P2H-100 |

| Condition | Used |

| Serial Number | P2H-100-29990 |

| Stock Number | 5963 |

| MODEL NUMBER | P2H-100 |

| SERIAL NUMBER | P2H-100-29990 |

| CAPACITY | 112 TONS |

| BOLSTER AREA | 48" LR x 31.5" FB |

| SLIDE ADJUSTMENT | 3.94" |